Indonesia’s Factory Automation Trend and Agent-Led Innovation

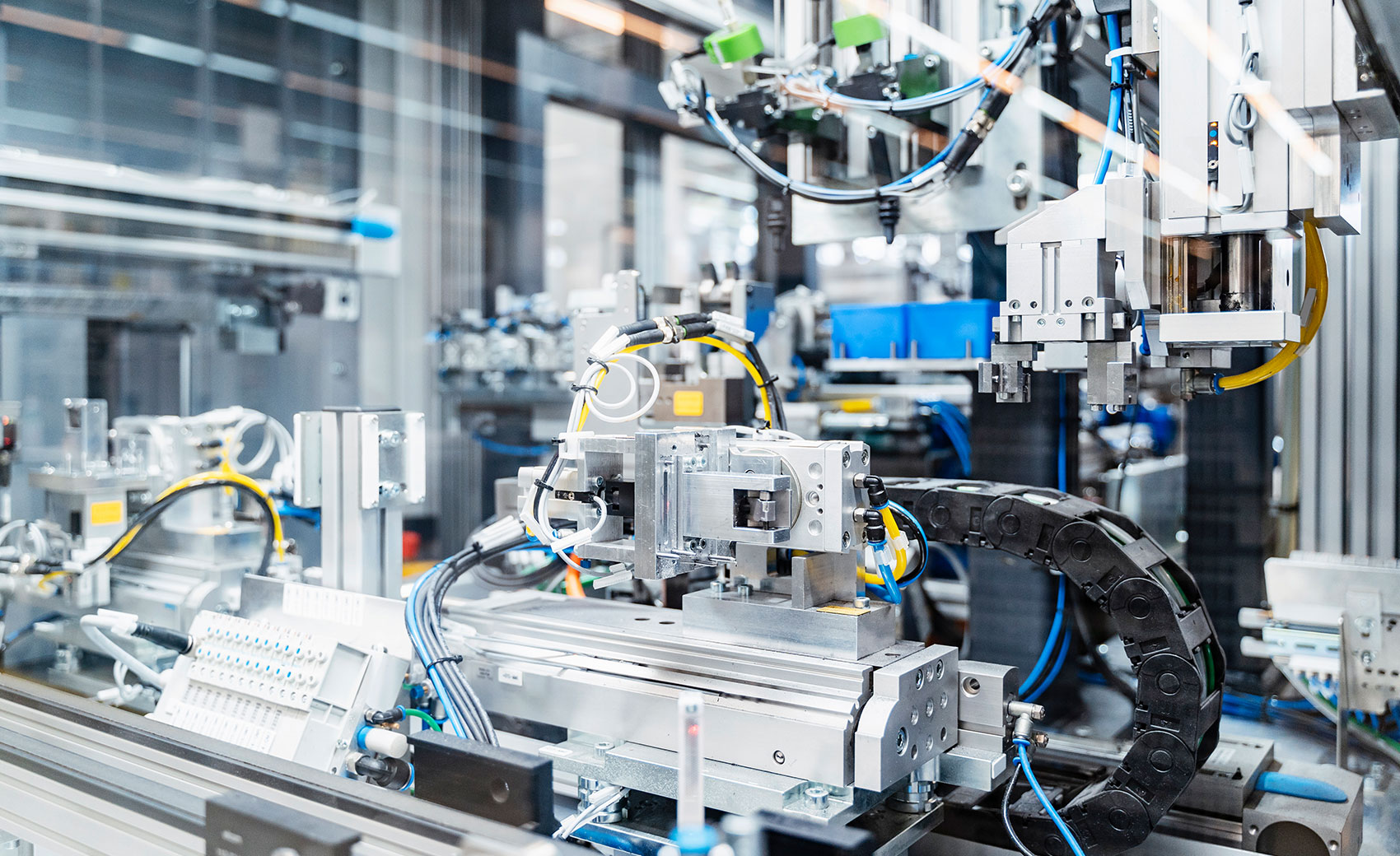

Indonesia’s manufacturing sector is undergoing a transformative phase driven by advancements in automation and Industry 4.0. As businesses shift toward smarter production systems, sourcing and manufacturing strategies must also adapt. Factory automation has become more than a buzzword—it’s a competitive necessity, particularly for companies aiming to meet international quality standards and delivery timelines.

But as automation accelerates, so does the need for on-ground expertise. This is where Indonesian sourcing agents are playing a crucial role—not just in connecting buyers to factories, but in navigating the complexities of this new digital industrial landscape.

The Push for Automation in Indonesia

Indonesia’s government, through initiatives like Making Indonesia 4.0, is encouraging manufacturers to embrace digital transformation. From automotive to textiles and consumer goods, factories are integrating robotics, machine learning, and IoT-enabled machinery to enhance productivity, reduce errors, and optimize labor costs.

Rising labor wages, increasing demand for consistent product quality, and global pressure to meet sustainability goals have fueled the shift toward factory automation. Factories adopting automation are better equipped to handle bulk orders, manage time-sensitive deliveries, and reduce operational waste.

However, many international businesses still face challenges when trying to identify reliable, tech-savvy suppliers in Indonesia. This is where a bestsourcing agent Indonesia can help bridge the knowledge and operational gap.

Why Automation Requires Agent-Led Solutions

Automation doesn’t just change machines—it alters how factories operate, plan, and communicate. When evaluating a factory, it’s no longer enough to ask about capacity or pricing; buyers must now inquire about a supplier’s digital capabilities, system integrations, and data management protocols.

A bestsourcing agent Asia can evaluate automation readiness. Agents often conduct site visits, assess the age and type of machinery used, and determine whether a factory’s automation investments align with the buyer’s expectations.

By vetting suppliers on these criteria, agents ensure that buyers don’t overcommit to facilities lacking technical reliability. Moreover, these agents assist in real-time tracking, defect reporting, and data-driven decision-making—all of which are enhanced by factory digitization.

Agent-Led Innovation in the Sourcing Process

Traditionally, sourcing agents served as mediators. Today, they function more like supply chain strategists. With the rise of automation, agents are innovating their services to include:

-

Factory automation audits

-

Digital inspection reports

-

Integration with client ERP systems

-

Production timeline simulations

-

Risk analysis for machine downtimes

By adding value beyond price negotiations, sourcing agents contribute to strategic growth and operational efficiency.

Benefits of Factory Automation for Global Buyers

Buyers who partner with modern Indonesian factories gain several benefits, including:

-

Improved product consistency: Automated processes reduce human error, resulting in better-quality goods.

-

Higher output speed: Robotics and intelligent assembly lines drastically reduce cycle time.

-

Data-backed production: Factories using smart sensors and IoT can provide real-time updates on production progress.

-

Scalability: Automation enables manufacturers to meet seasonal demand surges or scale down without disrupting operations.

These advantages allow global buyers to meet the rising demands of fast-paced markets while staying cost-effective.

The Role of Agents in Supplier Selection and Onboarding

Identifying suppliers that have adopted factory automation isn’t always straightforward. Listings may not reveal the full picture, and language barriers can prevent accurate assessments.

A bestsourcing agent Indonesia offers boots-on-ground knowledge, including:

-

Understanding of local manufacturing clusters adopting Industry 4.0

-

Relationships with forward-thinking factory owners

-

Cultural awareness in contract negotiations related to tech upgrades

-

Custom onboarding processes tailored for automated production systems

Agents help international buyers transition from outdated supply chains to smarter ecosystems without risking quality or compliance.

Challenges in Automation Integration

Despite the benefits, factory automation in Indonesia isn’t without its hurdles. The high cost of automation equipment, limited skilled technicians, and maintenance requirements can delay full adoption. Agents play a vital role in mitigating these risks by offering contingency planning, recommending phased automation adoption, or sourcing hybrid production models that blend manual and automated processes.

Automation in Action: Real-World Case Example

A U.S.-based electronics brand sought to move its plastic molding operations from China to Indonesia to reduce costs. However, the transition required a factory that could deliver exacting quality standards and consistent volume. With the help of a bestsourcing agent Asia, the company partnered with a supplier in West Java that had recently integrated semi-automated mold injection systems and AI-powered inspection tools.

The result was a 20% drop in defects, 18% improvement in delivery time, and a scalable production model that enabled the brand to expand into Southeast Asian markets with confidence.

Looking Ahead: What to Expect in 2025

As Indonesia continues to roll out its smart manufacturing policies, more factories are expected to invest in automation, especially in major industrial hubs such as Bekasi, Surabaya, and Batam. Concurrently, sourcing agents will continue to expand their services, offering AI-driven supplier evaluations and blockchain-enabled transaction transparency.

Buyers should remain vigilant and choose partners who not only understand traditional sourcing but can also navigate the new terrain of digitized manufacturing.

Final Thoughts

The automation wave is reshaping Indonesia’s manufacturing backbone, creating both opportunities and complexities for global businesses. But technology alone isn’t the answer—successful sourcing also depends on the guidance and adaptability of experienced local professionals.

By partnering with a bestsourcing agent Indonesia, companies can make informed, tech-driven sourcing decisions that align with their long-term growth strategies. These agents not only understand the nuances of automation but also ensure that innovation translates into reliability and performance across your entire supply chain.